Thermoplastic Elastomer Ether Esters: What are they, how do they work?

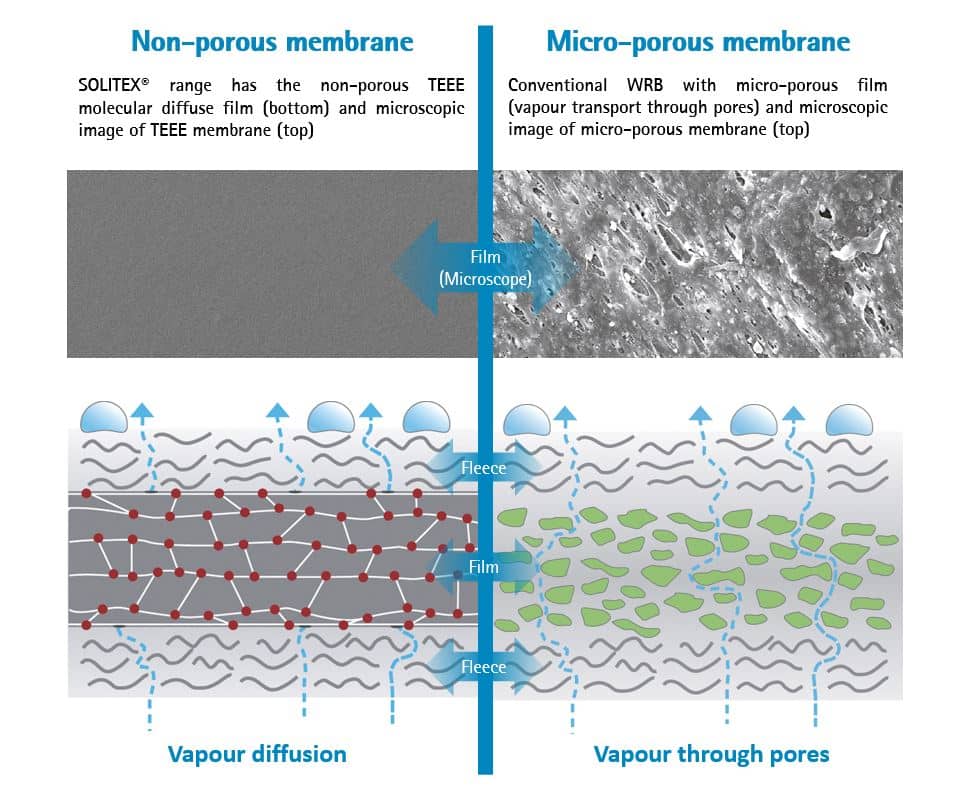

Exterior membranes for roofs and walls by pro clima incorporate a monolithic Thermoplastic Elastomer Ether Ester (TEEE) film. The TEEE forms a state-of-the-art Weather Resistive Barrier (WRB) and when combined with TESCON EXTORA® forms the SOLITEX® system. The membrane, unlike conventional vapour permeable membranes, has no pores. TEEE is completely waterproof and wind/airtight. The membrane actively transports water vapour through molecular diffusion across the thickness of the TEEE film – an engineered property of this functional film.

Aren’t all vapour permeable membranes the same?

If vapour/water is present on the surface of the membrane, even the slightest differential in vapour pressure across the membrane (inside to outside) will promote vapour movement from one side to the other and dry out the moisture. Consequently, the membrane is very vapour open (0.4 MNs/g, 2.5 µg/Ns). Conventional vapour permeable sarking membranes and underlays depend on creating a micro-porosity in a normally vapour closed material (PE or PP). In the production process these materials are made vapour open by either spun bonding them into a PE mesh, puncturing the PP or stretching the PP with calcium carbonate CaCO3 additives in production. These micro-pores then allow gaseous water vapour molecules to be moved through the water-resistant layer via the micro-pores.

By being porous, perforated or stretched, these materials may not be 100% airtight. They are vapour open because water-vapour molecules transfer through the micro-pores. When the pores are made very small – nanometre scale – a relatively high vapour pressure differential is then required for vapour to actually dry outwards through the pores, but the water hold out is improved. If the actual vapour permeance (per ASTM E96B) is high, it may be achieved with bigger pores or large perforations. If you can easily blow through the membrane when placing it over your mouth, the pores are probably large – very vapour open, and not very airtight, and possibly not even watertight under driving rain conditions.

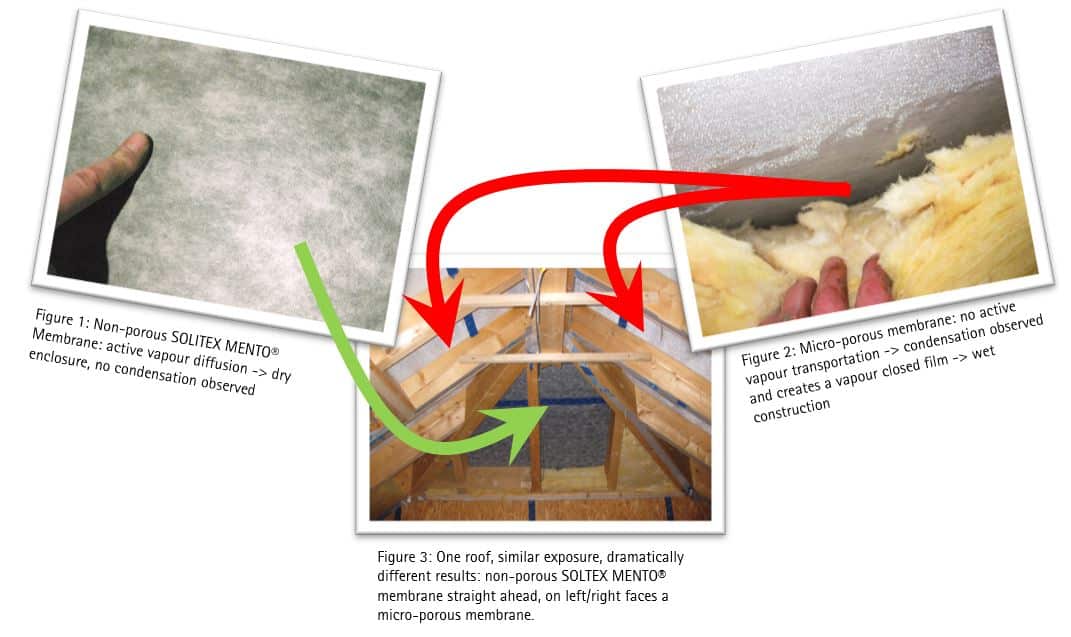

In one case it was observed that the SOLITEX MENTO® membrane with TEEE remains dry (Figure 1). In the same roof the microporous membrane was observed to have condensation forming (Figure 2).

The example above shows that an actively vapour open SOLITEX MENTO® membrane remained dry in a scenario where humidity was allowed to enter a roof enclosure with compromised interior airtightness. Water vapour is transferred very quickly across the TEEE allowing it to remain dry.

The conventional passively vapour open membrane in the same building showed condensation visible in Figure 2. It looked like the membrane was leaking, but the moisture is actually interior humidity condensing.

How is a vapour permeable membrane waterproof?

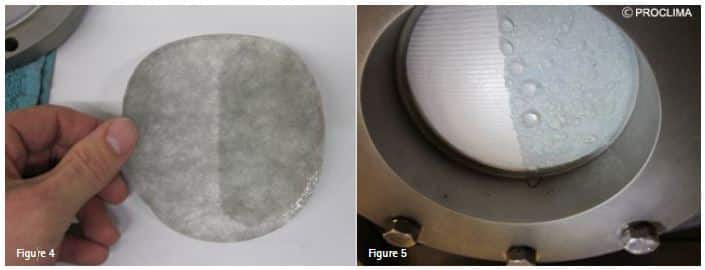

A micro-porous or perforated membrane is “waterproof” because the surface tension in liquid water holds the drops together and prevents water beads from passing through the membrane. But if that tension is broken by surfactants such as oils, wood preservatives, wood tannins, soap or contaminants, the waterproofing becomes compromised.

In contrast, the monolithic film in the pro clima SOLITEX® product range are completely waterproof. In the lab tests shown below to the left you can see the effect of applying oil to membranes before testing the water column (ISO 811) of each membrane (Figure 4 & 6). The conventional membrane leaks at low water pressures (Figure 5), while the SOLITEX MENTO® membrane stays dry at a much higher column (notice the difference in bulge). This demonstrates that the waterproof qualities of the TEEE work even when exposed to surfactants such as oil.

SOLITEX® range uses a monolithic membrane and is waterproof (ISO 811) up to lab test limitation of 10 meters head of water. Half of each membrane sample is coated with oil without any effect on waterproofness as seen in Figure 7.

Surfactant contamination on construction sites will have no effect on the water resistance of SOLITEX® products.

Micro-porous membrane

Non-porous membrane

Preventing wind washing

The pro clima SOLITEX® range with a monolithic membrane is absolutely wind & airtight. ASTM E2173 test results show that the material is so airtight that it exceeds the capabilities of the lab calibration – and goes above and beyond the Air Barrier Association of America (ABAA) requirements and certainly well above the thresholds specified in AS/NZS 4200.1 or NZS 2295 measured using ISO 5636-5 (AUS) & BS 6538.3 (NZ).

The pro clima WRB roof & wall systems offer the ultimate protection against wind-washing of insulation when taped with TESCON® tapes and following the other instructions found on SOLITEX MENTO® and SOLITEX EXTASANA® product pages.

Pro clima full scale weather testing in NATA and IANZ accredited laboratories has demonstrated world class weather tightness with the SOLITEX EXTASANA® flexible membrane system and rainscreen cladding.

Three layers – each with its own function

All pro clima WRB membrane systems are multi-layered products, with each layer having specific properties to assure the product offers first class performance during installation and the life of the building. The top layer serves as a protective cover made with a PP microfiber fleece. This offers the external exposure resistance needed for both roofs and walls.

When SOLITEX MENTO® is used as roof underlayment, the top layer offers slip resistance, while also protecting the TEEE layer below.

The TEEE functional layer is located in the middle of each product, providing the active vapour permeability and waterproofing properties of the material. The SOLITEX® product range allows UV exposure prior to cladding of:

- SOLITEX MENTO® 1000: 30 days

- SOLITEX MENTO® 3000: 90 days

- SOLITEX MENTO® 5000: 180 days

- SOLITEX MENTO® PLUS: 180 days

- SOLITEX MENTO® ULTRA: 180 days

- SOLITEX EXTASANA® (NZ): 180 days

- SOLITEX EXTASANA® (AUS): 180 days

- SOLITEX EXTASANA ADHERO® (NZ): 180 days

- SOLITEX EXTASANA ADHERO® (AUS): 180 days

The TEEE functional layer also has the added benefit that it holds the product together, acting as the bonding agent applied in a high temperature process it eliminates any need for hot melt adhesives giving SOLITEX MENTO® and SOLITEX EXTASANA® ultimate temperature resistance behind hot cladding materials.

SOLITEX® products without reinforcement scrim have shown no heat shrinkage up to 100°C in accordance with Australian and New Zealand Standard AS/NZS 4200.1. This elevated test temperature is 30°C above the requirement.

The heat shrinkage @ 70°C in accordance with AS 4200.1 and ADTM D 1204:

- SOLITEX MENTO® 1000, 3000, 5000, ULTRA: 0.0% shrinkage

- SOLITEX MENTO® PLUS: 0.4% shrinkage

- SOLITEX EXTASANA® : 0.0% shrinkage

- SOLITEX EXTASANA ADHERO®: 0.0% shrinkage

The top fleece protects the TEEE film from direct UV exposure during installation. Polymers are engineered for enhanced UV tolerance. Heavier duty fleeces provide more protection and allow for longer UV exposure prior to cladding.

TEEE: Thermoplastic Elastomer Ethyl Ester – is a material that combines the flexibility of rubber with the strength of a membrane, resisting tears, abrasion and corrosion. It also has good resistance to surfactants.

The bottom microfiber fleece protects the TEEE layer above from damage during construction.

Adapted from an article published on: https://foursevenfive.com/blog/the-pro-clima-solitex-mento-difference/

Related Posts

Categories

Authors

Recent articles

- Drier Education: An Insight into the MOE’s Weathertightness Design Requirements for School Buildings March 26, 2024

- Insulating Kitchen and Bathroom Walls March 12, 2024

- Renovating the EnerPHit way in the ‘Winterless’ North October 3, 2023

- Energy efficiency is essential. But can we afford it? May 5, 2023

- A Builder’s Journey Towards a Healthier Future with His Own Passive House Build January 12, 2023