Improving Thermal Performance with Triple Connected Windows

How to ensure standard thermally-broken windows are positioned to succeed.

Window Choice

R-values and argon, performance vs installed performance, double glazing, timber, uPVC, aluminium; no matter what you choose, windows are the weakest point in the thermal envelope — a “thermal wound” in the words of David Waters from APL.

So let’s reduce the assumption of knowledge in a complicated area. We’ve been running a research project in conjunction with Technoform Bautec who produce the thermal-break part of thermally broken joinery, and InsideOut (building performance experts) to better understand windows.

Surface Temperatures

Everyone can understand the temperature. Stating surface temperatures of joinery elements is a great step toward better understanding, specification and performance. In this first article on the topic, I make the claim that standard aluminium joinery is good for cowsheds and not residential construction.

Thermally broken aluminium, however, is worthwhile but must be installed slightly differently to allow the thermal break element to perform.

Option One: The Ugly

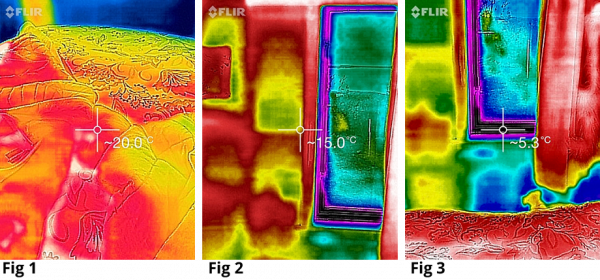

Non-thermally broken double glazed windows will meet ‘deemed to satisfy’ requirements of H1, but no matter what type of high-performance glazing is used, the internal surface temperature of the window frame will still only be 5°C when the outdoor air is zero centigrade (well, 5°C degrees if you heat internally to 20°C degrees anyway). See Fig 1,2,3. So what is the problem?

– Reduced comfort levels around windows

– Condensation forming on window frames

– Increased heat loss due to conduction through aluminium frames

– Increased energy bills as comfortable indoor temperatures are hard to maintain

Option Two: The Bad

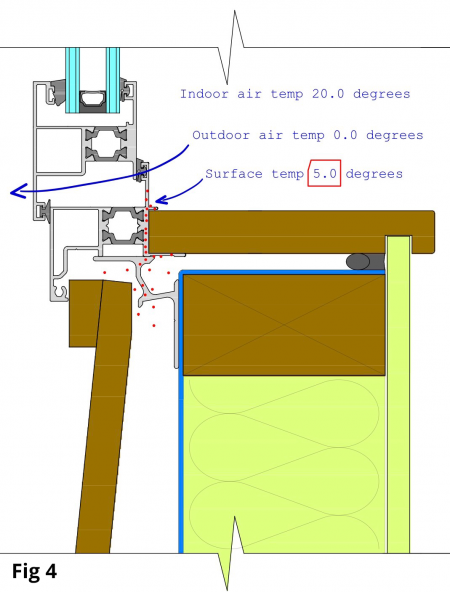

Another option is thermally-broken frames installed to E2/AS1 (still hanging outside the building envelope and requiring support from the WANZ bar). According to thermal simulations, thermally broken frames will achieve a 1°C increase in surface temperature at the sill compared to non-thermally broken frames installed the same way. 1°C. Eins. Un. Een. Satu. Tahi. Aon.

When paying 10% to 20% more for thermally broken frames, we should expect better performance. So what is happening?

There are two issues at play. Firstly, the WANZ bar which supports the thermally broken window creates a thermal bridge bypassing the thermal breaks in the window. Secondly, the frame sits over a ventilated cavity that again bypasses the thermal breaks.

See Fig. 4. The red dots indicate the thermal bridging.

Option Three: The Good — Triple Connected Windows

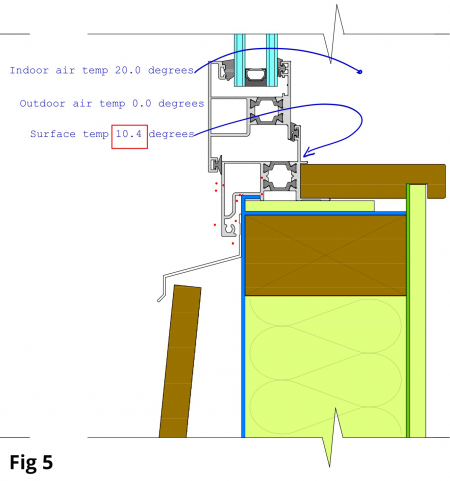

Take the existing profile of thermally broken aluminium and move it toward the insulation line of the building. See Fig 5.

- Connect it for weathertightness at the weathertightness plane (at the outside) while still allowing for possible leakage at the mitre joints.

- Include insulation to connect wall insulation to thermal break

- Connect for air-control in a permanent fashion with tape rather than expecting foam to permanently prevent air movement.

By simply moving the window in line with the insulation layer, we can increase the internal sill surface temperature of thermally broken frames from 5°C to 10.4°C degrees. Moving the frame means the aluminium WANZ bar is no longer required and that the thermal break no longer sits in a ventilated cavity. This means that:

– There are increased comfort levels around windows

– The instances of condensation forming are reduced

– Heat loss through thermal bridging is eliminated

– A more comfortable internal environment is created

I’m not offering design advice for rearranging flashing details here, but I suggest considering how windows connect with rebated block construction and applying the same principles. One example which includes thermal wall elements is the ICF sill detail in the link above.

Significant conclusions and application of common sense so far:

– Increasing a window’s R-value through the glazing has no influence on the frame’s internal surface temperature.

– Recessing thermally broken frames allows the thermal break to perform.

– Detailing for E2/AS1 weathertightness alone is not improving the thermal performance of joinery.

– Aluminium joinery without a thermal break should only be specified for temporary shelter of furry animals, not for humans.

In the next article, we’ll show some specific temperatures for real-world installed windows and how this needs to be read in conjunction with WEERS ratings.

Tags In

Categories

Authors

Recent articles

- Drier Education: An Insight into the MOE’s Weathertightness Design Requirements for School Buildings March 26, 2024

- Insulating Kitchen and Bathroom Walls March 12, 2024

- Renovating the EnerPHit way in the ‘Winterless’ North October 3, 2023

- Energy efficiency is essential. But can we afford it? May 5, 2023

- A Builder’s Journey Towards a Healthier Future with His Own Passive House Build January 12, 2023