Triple Connected Windows – Part 2

It is very important that all aspects of the window are taken into consideration; frame system, double glazing, window size and the connections between the window and the wall.

Generic window values are not good enough

How we measure window thermal performance, in theory, does not reflect how windows perform in practice. The issue with generic window values in NZS 4218 (2009) is that it evaluates one window type and configuration and assumes that the thermal performance of this window is representative of all windows made of this type. In reality, this is never the case. Are we being honest when we say a small toilet window performs the same a triple stacker sliding door? I think the answer is no…

According to NZS 4218 (2009), aluminium windows with clear double glazing achieve an R-value of 0.26 (H1 minimum for energy criteria) and thermally broken windows with clear double glazing achieve an R-value of 0.31. If we take into consideration the actual window configuration and the E2/AS1 installation method, we find that theory is not even remotely close to reality.

The connection between the window and wall is critical in measuring actual thermal performance. The thermal analysis of generic windows only takes into consideration the glazing and the frame in a single size and configuration, when in practice every window is a different size and must be installed into a wall.

The graph below shows the thermal performance of a double glazed aluminium window in various sizes after taking into consideration the E2/AS1 installation methodology. As you can see all but the very largest window sizes don’t come anywhere close to the generic minimum value of 0.26.

What could we be doing better?

It is clear that aluminium clear double glazed windows installed to E2/AS1 do not always meet energy code requirements. In order to increase window performance above an R-value of 0.26, we instead need to use a higher performance frame in conjunction with a higher performance installation detail.

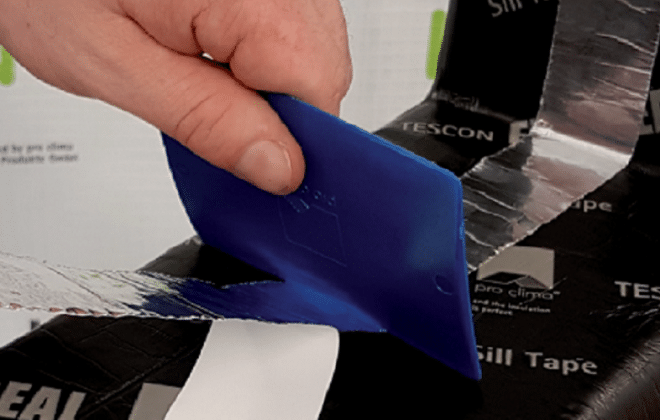

An installation using the triple connect approach with pro clima tapes aligns the window system with the wall insulation and moves the insulated portion of the frame back from the cold ventilated cavity. What results is a window that not only meets the H1 energy code requirement, but also substantially increases the frame’s internal surface temperature (by 5°C at the sill), meaning fewer instances of condensation, and increased comfort levels within the building.

The graph below highlights the performance of a thermally-broken aluminium window with clear glazing installed according to the triple connect system and E2/AS1. Just like aluminium windows, thermally broken windows installed according to E2/AS1 perform lower than the expected generic R-value of 0.31. However, if windows are installed according to the triple connect method, in many circumstances thermally broken windows outperform expected generic window performance.

Installing thermally broken aluminium windows with the triple connect approach ensures the window will perform close to or above expected generic value as well as the minimum R-value requirement of 0.26.

Triple Connect vs E2/AS1

Comparing thermally broken windows installed using the triple connect system against an aluminium window installed using E2/AS1 installation details it is clear that there is a substantial difference in thermal performance.

The difference is more pronounced in smaller window sizes. The graph below shows that small thermally broken windows achieve an R-value of 0.29. This is 60% higher than standard aluminium frames that only achieve an R-value of 0.18.

As the size of a window increases the proportion of glazing area relative to the frame area also increases, meaning it has a greater influence on thermal performance. However, even the largest aluminium window simulated which achieved an R-value of 0.26 performed 27% below thermally-broken windows.

Why not just specify better glass?

As a final note, it is worth mentioning that to increase the thermal performance of aluminium windows you could also install glazing with a low e coating, argon gas and warm edge spacers.

However, this expense alone will not stop condensation from forming on the frames. It is very important that all aspects of the window are taken into consideration; frame system, double glazing, window size and the connections between the window and the wall.

Article co-authored by Antony Hopper at Technoform Bautec and based on current research by InsideOut Ltd.

Tags In

Categories

Authors

Recent articles

- Drier Education: An Insight into the MOE’s Weathertightness Design Requirements for School Buildings March 26, 2024

- Insulating Kitchen and Bathroom Walls March 12, 2024

- Renovating the EnerPHit way in the ‘Winterless’ North October 3, 2023

- Energy efficiency is essential. But can we afford it? May 5, 2023

- A Builder’s Journey Towards a Healthier Future with His Own Passive House Build January 12, 2023