Europe

Intelligent

Air

Barrier

Contributes

to

Sustainable

Tauranga

Home

A sustainable home isn’t just a standard build, it is a science project. Kirstie

pro clima contributes to the client’s brief for an energy-efficient home.

Kirstie became passionate about energy-efficient design after completing a renewable energy course with the Southern Institute of Technology (SIT). This spurred her desire to build a sustainable home in Tauranga. The spec was to achieve an environmentally sustainable home, utilising passive heating and cooling through build orientation, insulation, airtightness, and energy-efficient materials.

A sustainable home isn’t just a standard build, it is a science project where the environment needs to be considered throughout the entire process, allowing it to organically transform where necessary, says Kirstie.

Many people in the building industry do not comprehend how exact this type of build needs to be and the ‘that’ll be fine’ attitude isn’t acceptable and can have an impact on the overall performance of the home.

How was this project implemented?

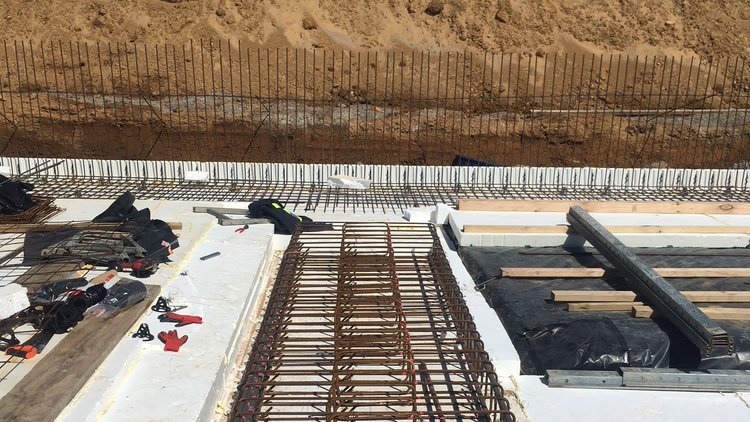

The home's structure has been designed using Eco ICF. Eco-Block walls are built using expanded polystyrene side panels held together by high-density plastic webs and connectors. Reinforcing bars are installed, and concrete is then poured into the centre of the two panels, which provides the wall with structural strength. After the concrete cures, the side panel remains in place and provides insulation for the walls.

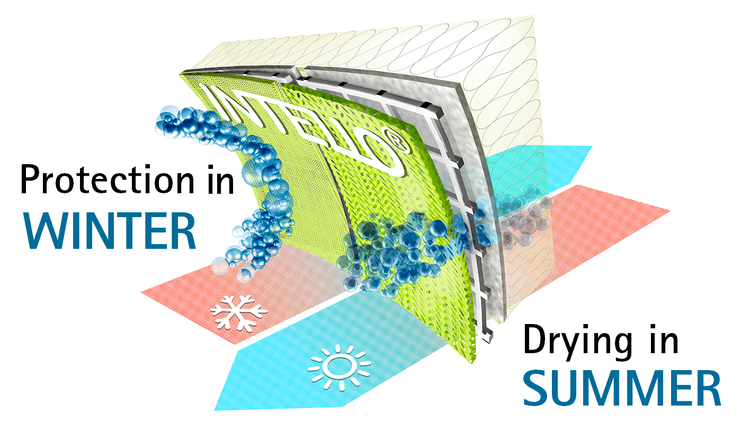

To continue the airtightness layer in the ceiling, pro clima INTELLO® PLUS Intelligent Air Barrier was installed under the roof trusses and was taped to EPS polystyrene walls. This layer protects the roof cavity from any internal moisture and improves the thermal performance of the insulation in the ceiling. A suspended ceiling was installed below the INTELLO® PLUS layer to allow the installation of energy-efficient LED lights and the Zehender ventilation pipes to be installed below the airtight membrane and insulation level.

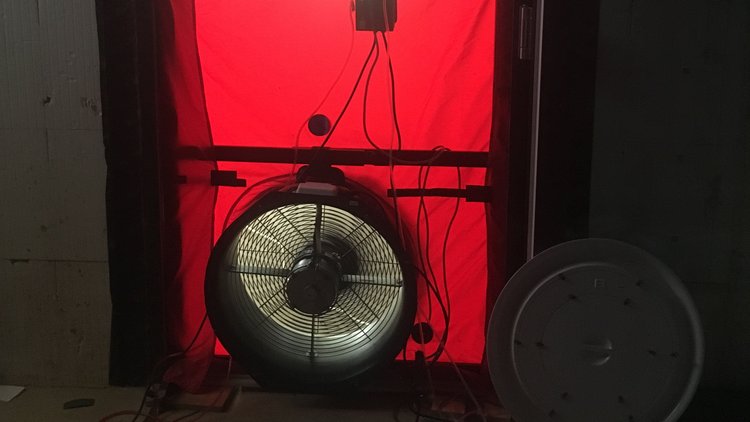

The house is located on a highly exposed site, and the airtightness layer helps reduce wind noise. A Blower Door test was conducted, and a reading of 0.83 air changes per hour at 50 Pascals was achieved. Air was found to be leaking through the seals on the front door. The window company looked to rectify this with additional locking nuts, thereby reducing the exchange even more. This is still much more airtight than a home built according to the New Zealand Building Code, which can be as many as 5 to 10 air changes per hour.

I spent many hours walking around my home, to the amusement of the builders, chiselling out concrete overspill from foundations and refilling with foam to prevent a thermal bridge, says Kirstie.

I also followed behind the builders after they installed INTELLO®, checking seams and taping all pipe protrusions through the paper. Many would say I was pedantic, but achieving an initial Blower Door test of .85 and enjoying 25°C of passive heating as I sit in my living room, knowing it is 7°C outside with 20km/h wind gusts, makes me realise that it was all worth it! One of the most amusing conversations I recall was about organising the Blower Door test. While explaining the process, a couple of the builders highlighted their concerns about remaining in the house in case they suffocated! We all survived. Partway through the build, a wise tradesman offered me advice: ' A new build is a count of 3… you’ll do it once; it will take twice as long and cost three times as much.'

A Zhender Heat Recovery system was installed to ensure that fresh air is supplied to all living and bedrooms while stale, moist air is removed from bathrooms and kitchens. The energy is recovered from the waste air and used to heat the fresh incoming air. On a lovely summer’s day, the doors and windows can be opened to make the most of the good weather.

The hydronic underfloor heating system is installed on the 300 mm ECO floor slabs for the second floor, and the ground floor has Expol insulation under the slab, isolating the foundation and footings and preventing thermal bridging between the ground and building envelope.

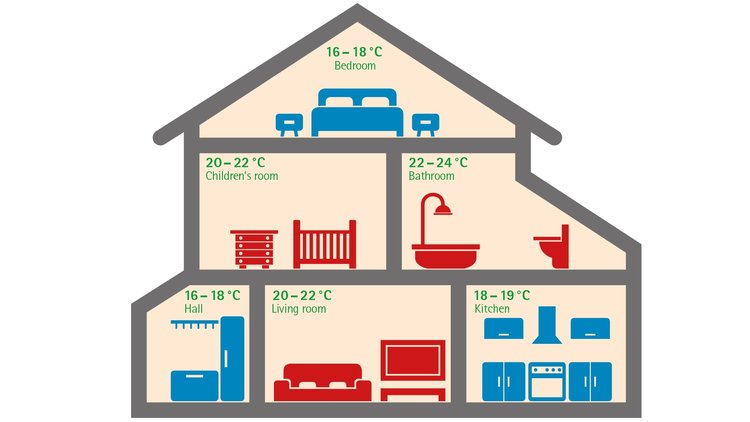

With the UFH running only between 3 am and 7 am, the home achieved room temperature, on average, 10 – 15°C warmer than outdoors. There were only curtains in the main bedroom, so I am expecting the retained overnight heat to be higher in winter.

Double glazing was selected for the north side of the home to maximise passive heat gain during winter (in summer, the sun is blocked by 1.1 m soffits), and triple-glazed, tinted glazing was used on the Southeast and West to prevent heat loss in winter and overheating with morning/evening sun in summer. The windows have thermally broken UPV frames.

Would I build again? During the process, my answer would have been a resounding no way, but now, as I reach the final stages, I realise I have created a large home that costs less than the average family home to run. I learnt so much about the building industry, the relationship between materials and costs and how important it is to be tenacious, even if you are considered a pain in the backside for the builders. So yes, I would do it again.

Congratulations, Kirstie, on your persistence and success!

Enjoy.

-

Architect - Coralie Rose

-

Designer - Kirstie Brown

-

Builder - ZJ Builders

Intelligent Airtightness

Moisture damage to structures and protection measures Moisture can enter into building structures in many different ways, and it is impossible to prevent a certain level of moisture loading However, if moisture levels are too high, moisture damage to structures can result To ensure a structure is protected against moisture damage, the drying reserves possessed by the building component are much more important than the degree of tightness of the vapour check Vapour barriers with high diffusion resistances allow for barely any drying from the component to the inside A high degree of protection against moisture damage to building structures can be achieved with intelligent airtightness.

Energy Efficiency

A thermally insulated, airtight building envelope plays a major role in determining how comfortable and pleasant an indoor environment is for us and how well we can work, learn or relax there. The air temperature has the strongest effect on our perception of comfort level: a temperature range of between 20 °C and 23 °C in homes is regarded as comfortable in winter, while temperatures of up to 26 °C are perceived as pleasant in summer. In this context, airtightness has a crucial influence on the effectiveness of thermal protection in both winter and summer.