Sustainability

Your

Sustainable

Companion

From March 2024, the fleece on pro clima INTELLO and INTELLO PLUS has been made from from 50% recycled material.

The best scenario regarding environmental protection is when resources are not used at all! For this reason, pro clima is delighted to launch the first humidity-variable vapour control membranes with a high fraction of recycled material in their fleece layers: INTELLO® and INTELLO® PLUS.

Pro Clima is giving leftovers a second chance

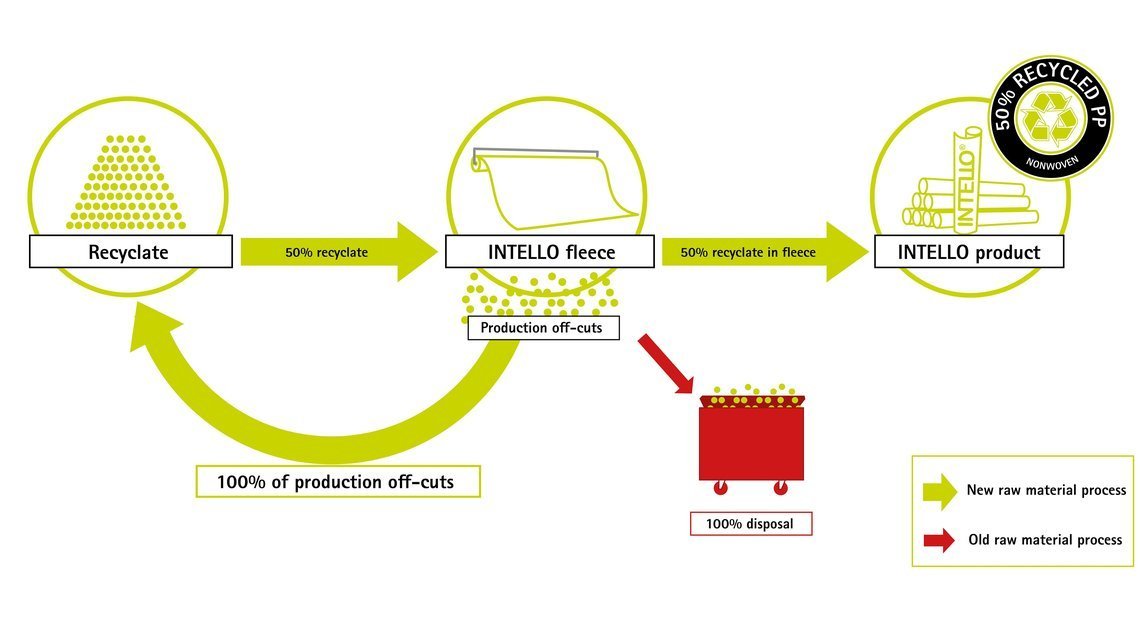

There is always some waste involved in production processes, which also applies to manufacturing our successful INTELLO® and INTELLO® PLUS high-performance vapour control membranes. However, the good news is that pro clima has now succeeded in integrating new technology into the production process that allows us to recycle and re-use waste off-cuts of INTELLO® and INTELLO® PLUS.

As a result, Pro Clima is currently the only European producer of intelligent vapour control and airtightness membranes on the marketplace, with a recycling fraction of 50% of the membrane fleece. This makes INTELLO® and INTELLO® PLUS even more ecologically beneficial and sustainable.

As Good as New – Only Better!

High-quality off-cuts from fleece production are a valuable secondary raw material. They have the same consistent quality level as new plastic – but with one crucial difference: they are less environmentally burdened. After all, 50% less primary raw material means less material needs to be purchased and transported to our production facilities. The recyclates are processed on-site, which saves on energy and non-renewable resources. This optimised production process also has benefits in terms of reduced waste disposal. More recycling automatically means less waste. The waste generated during production start-up and shut-down can be reused as valuable raw materials, just like off-cuts during normal production. Here, too, less waste to be collected and disposed of means less transport fuel is consumed. The best of all is that the fleece and, as a result, the end products INTELLO® and INTELLO® PLUS retain the same high levels of quality and durability and have the same technical properties as before.

Maximal Minimalism

With this new development, Pro Clima has reduced the use of non-renewable resources to a minimum. The bottom line is that the new production processes for INTELLO® and INTELLO® PLUS will save at least 225,000 kg of new plastics every year. In concrete terms, this means:

-

Reduced use of fossil raw materials

-

Less energy consumption due to less transportation of raw materials and waste

-

Less waste to landfill

All in all, Pro Clima has taken another important step along the way to making its production even more sustainable. And this development process will, of course, continue. Watch this space!

Black

is

the

New

Green!

Plastics are far too valuable to be used just once.

Our new ORCON® CLASSIC tubes might not look it, but it’s possible that the plastic in them was once part of a yoghurt cup or a soft drink bottle! These black tubes are made entirely from recycled post-consumer plastic. Specifically, old plastic waste, like packaging or single-use bottles from the deposit system, is now being repurposed into high-quality material to make the ORCON® CLASSIC tubes. Choosing this adhesive means you're picking a great product and supporting recycling, too.

The packaging may be black, but it’s 100% green.

From now on, our ORCON® CLASSIC and other popular adhesives sold around the world will come in black tubes made from 100% recycled plastic. It may seem like a small change to you, but it makes a big difference for the environment!

14 Tonnes of Plastic Saved – Worldwide!

By switching to recycled materials for multiple products used across the globe, pro clima will prevent 14 tonnes of new plastic from being produced each year. This leads to lower energy consumption during manufacturing, less dependence on fossil resources and supports the so-called circular economy.

This is just one of many steps we’re taking to cut energy use and conserve resources.

At Pro Clima, we’re always striving to reduce our environmental footprint. From eliminating plastic wrapping to using eco-friendly cardboard boxes, we’re committed to making a real difference because sustainability is at the heart of what we do.

Eco-Friendly

Innovation

100%

recycled

paper

membrane

for

sustainable

building

sealing

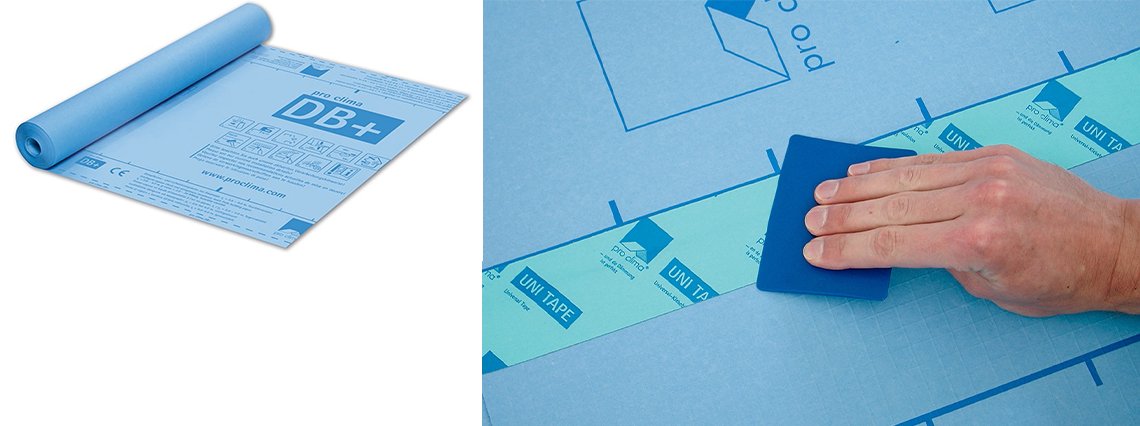

Some of you might already know that airtight membranes can also be made from paper. But did you know that our reinforced vapour control layer and airtightness membrane, DB+, is made entirely from 100% recycled paper?

No Compromise on Quality!

At Pro Clima, we're not just focused on ensuring the building is sealed effectively; we're also committed to high standards regarding environmental protection and resource conservation. This means protecting forests and minimizing waste.