Moisture Control

Moisture

Control

Protection Against Mould and Damage to Structures

Thermally insulated structures must be protected against moisture loading in warm indoor air. This task is carried out by vapour control and airtight membranes.

Suppose indoor air can flow unhindered through the thermal insulation. In that case, the air cools down as it penetrates further into the insulation until, eventually it reaches dew point and the water vapour in the air liquefies into condensation. This condensation can cause significant damage to building structures. Crucial load-bearing components can start to rot and may lose their structural strength.

Moisture can also lead to the formation of mould, which causes health problems. Many mould fungi release poisons – such as MVOCs (microbial volatile organic compounds) – and spores as secondary metabolic products that harm human health. These are a leading cause of allergies. Humans should avoid all contact with mould fungi.

A vapour check and airtight layer inside the thermal insulation can help prevent this kind of moisture damage to structures.

Intelligent airtight membranes offer significantly more reliable protection than conventional air barriers.

Condensation – Dew Point – Amount of Condensation

Thermal insulation in the building envelope separates warm indoor air, which has a high moisture content, from cold outdoor air with its low absolute moisture content. The physical behaviour of the air is responsible for the formation of condensation:

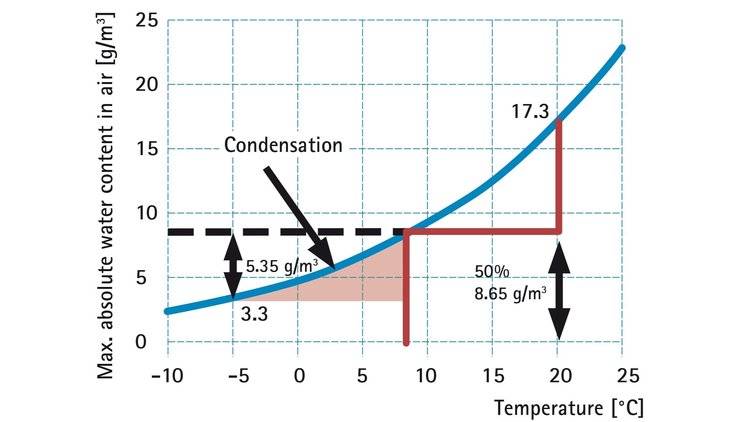

Warm air can hold more water than cold air. At higher relative humidities (e.g. around 65% or more in newly built buildings), the dew point temperature rises and, as a direct result, the amount of condensation increases too.

Fig.: Starting out from an indoor climate at 20 °C and 50% relative humidity, the dew point is reached at 8.7 °C. At a temperature of -5 °C, the amount of condensate formed will be 5.35 g/m³ of air.

Diffusion is Desirable – Convection is Not

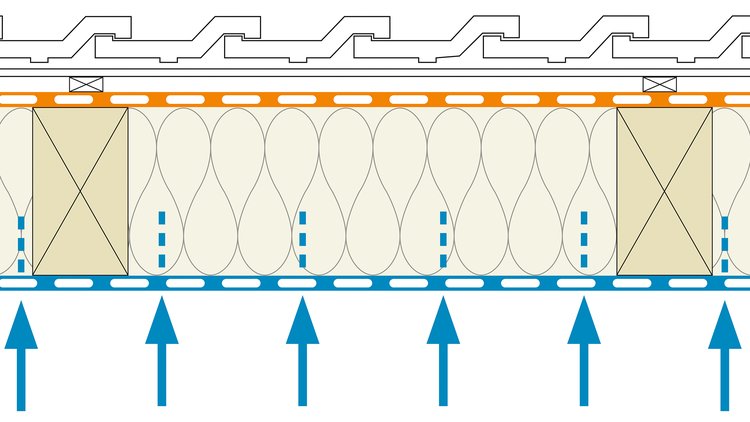

In contrast with convection, diffusion is a predictable and desirable process. Diffusion takes place due to a concentration or partial pressure difference for water vapour between the inside and outside. In this case, the mass transfer does not occur through leaks or gaps, but instead in the form of moisture passing through a monolithic, airtight material layer.

The direction of this diffusion is generally from the inside to the outside in winter and from the outside to the inside in summer. The entry of moisture into a building structure depends on the diffusion resistance (sd value) of the material. In Central Europe, the period with warm exterior temperatures is longer than the period with winter temperatures, which means that more moisture can dry out of the structure.

A vapour check membrane with an sd value of 2.3 m allows approx. 5 g of moisture per square metre to penetrate into the building structure each day in wintertime, according to DIN 4108.

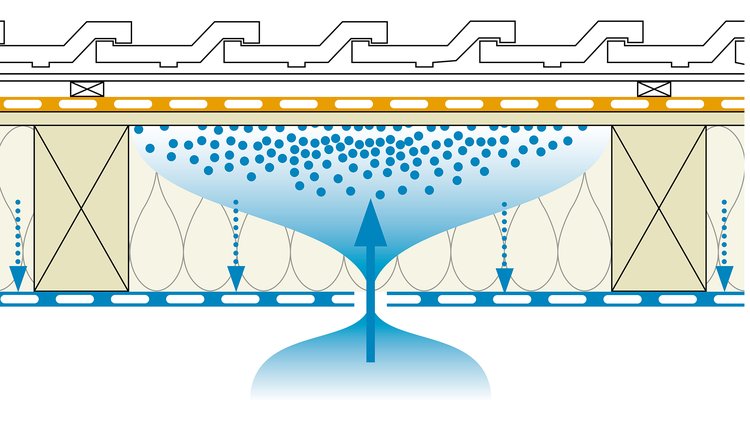

Air Flow (convection) is Problematic

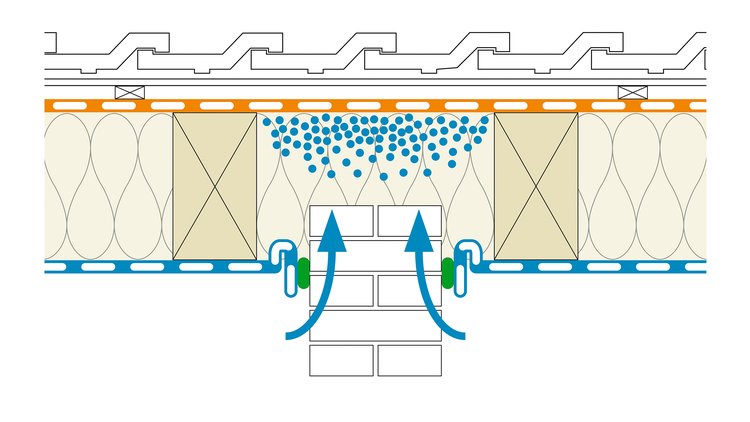

A flowing movement of air is referred to as convection. This can occur in thermal insulation structures if there are gaps in the vapour check layer. The temperature difference between the interior and exterior climates leads to an air pressure gradient, which the air flow then attempts to balance out.

Several hundred grams of moisture can enter the insulation due to convection in a single day and accumulate there in the form of condensation water.

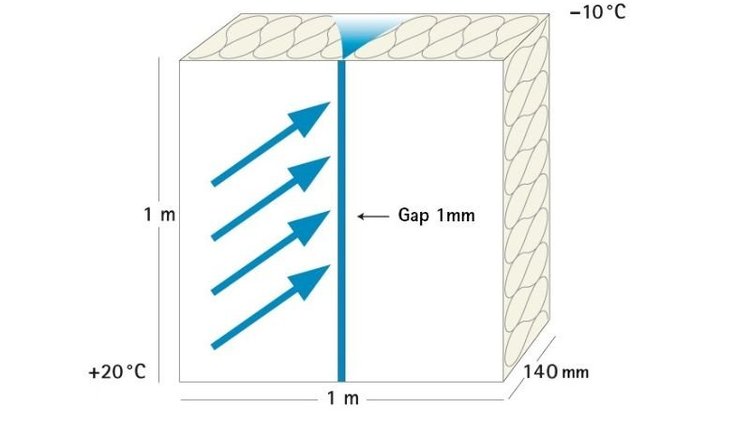

Example: 800 g of condensation through a 1 mm gap

0.5 g of water per square metre will diffuse into the building structure each standard winter day through a gap-free insulation structure with a vapour check with an sd value of 30 m. In the same period, 800 g of moisture per metre of gap length will flow into the structure by convection through a gap with a width of 1 mm in the vapour check. The amount of moisture is 1,600 times larger in the case of convection through a gap!

Small Gap, Big Problems!

How to Build a Better Tomorrow

To celebrate 20 years of INTELLO® and to raise awareness about healthier indoor environments, we've created a short documentary series highlighting key aspects of building quality homes for people. The series is comparing early 1900s villas with modern builds, exploring why many new homes still face issues with moisture, cold, and long-term structural problems.

Learn why airtightness matters and uncover the reasons behind cold, damp, mouldy, and deteriorating buildings in Aotearoa.

Small gap, big problems

Join us as we explore Airtightness — a concept often misunderstood in New Zealand. You may be surprised by what we uncover.

Airtightness Part 1

Why do early 1900s Villas remain the gold standard? Haven't we learned anything in the past 120 years?

Airtightness Part 2

Why are our new buildings still cold, damp, and short-lived?

Other Unplanned Sources of Moisture

Entry of moisture at the sides of building components

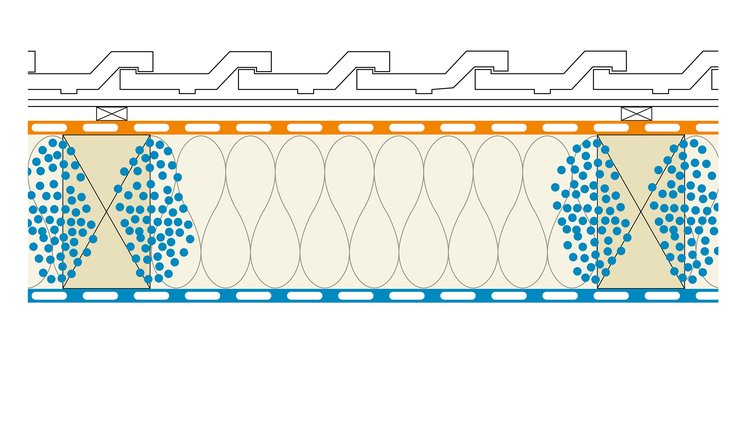

Flank diffusion: In this case, moisture enters into the thermal insulation at the sides of an adjacent building component. This adjacent component is generally airtight, but has a lower sd value than the vapour check. One example for a situation of this kind is a masonry wall with airtight plastering that penetrates into the insulation layer.

If structures that are closed to diffusion on the outside have vapour checks on the inside that allow little or no drying to the inside, there is a risk of an accumulation of moisture and of resulting damage to structures in the case of airtight design.

Moisture Contained in Building Materials

Damp construction materials: By their very nature, newly built structures can contain a lot of moisture in the building materials themselves. This example illustrates the amounts that can be involved: a roof with 6/22 rafters, e=70 cm and a wood density of 500 kg per cubic metre will have approx. 10 kg of wood per square metre; when this wood dries, the following amounts of water will be released per square metre:

- 1% drying: 100 g of water/m²

- 10% drying: 1000 g of water/m²

- 20% drying: 2000 g of water/m²

These quantities of moisture can subsequently enter into other parts of the building structure.

The Key Takeaways

- Moisture can enter into a building structure in many different ways. It is impossible to prevent a certain level of moisture loading.

- However, if moisture levels are too high, moisture damage to structures can result.

- Vapour check membranes provide more reliable protection than vapour barriers. Vapour barriers with high diffusion resistances permit very little drying from the component to the inside, and quickly become moisture traps.

- The key factor in preventing moisture damage to structures is the presence of significant drying reserves.

Airtightness & Moisture Management Study

The updated New Zealand pro clima Study on Airtightness & Moisture Management is based on factual evidence and computer simulations of heat and moisture transport in building structures. It addresses prevalent issues in New Zealand construction, aiming to combat dampness and improve indoor air quality.

The pro clima system offers practical, cost-effective solutions for creating healthy, comfortable, and energy-efficient living environments.