High-Performance Vapour Control Layer

Advantages

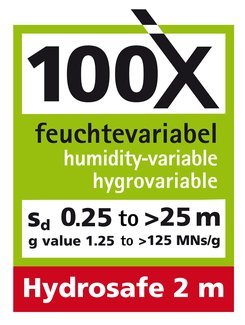

- Promotes superior drying capacity with hydrosafe® technology

- Intelligent airtightness system (IAS) for warm, dry, healthy buildings

- Maximises the performance of thermal insulation

- Highly diffusion-resistant in winter

- Superior back-diffusion capacity in summer

Areas of application

INTELLO® is a market leading intelligent air barrier for all construction types, providing superior energy efficiency and moisture control. INTELLO® maximises the performance of thermal insulation while restricting internal moisture from entering the building envelope. INTELLO® utilises hydrosafe® technology, providing optimal protection against structural damage and mould, even in the event of unexpected moisture intrusion.

Planning and construction guidelines

Areas of application

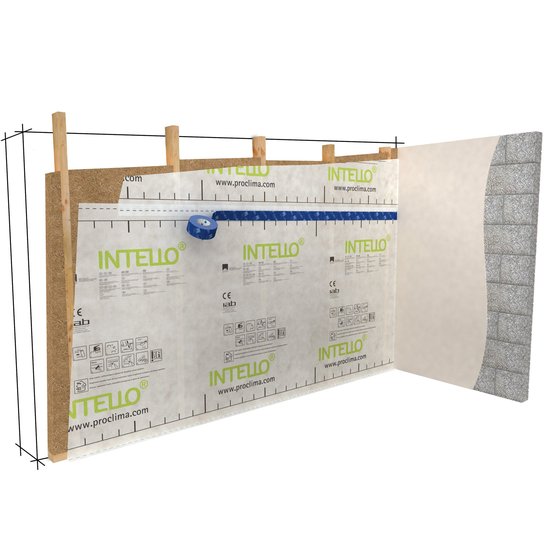

The INTELLO and INTELLO PLUS vapour control (alternate names: Vapour Control Layer, Smart Vapour Retarder) and airtight membrane is used as an air barrier for thermal insulation:

- In roofs, walls, ceilings, and floors

Applications on complex or demanding structures

By global standards, the INTELLO PLUS system also offers a particularly high level of potential freedom from structural damage for critical structures that are externally impermeable such as pitched roofs having a metal covering and sub-roofs made from bitumen roof sheathing, for flat roofs, green roofs etc. – even in locations with an extremely cold climate. Detailed information on the physics of thermal insulation is available in the study on “Calculating potential freedom from structural damage of thermal insulation structure in timber-built systems”.

- Study - for New Zealand

Use of fibrous insulation materials

The high degree of protection against moisture damage to structures offered by humidity-variable vapour control membranes is achieved by using fibrous thermal insulation materials that are open to diffusion, as the moisture must be able to diffuse through to the vapour control membrane for the purpose of drying during the summer climate.

Fibrous thermal insulation materials such as cellulose, wood fibre and rock or mineral wool are ideal here.

Use of diffusion-open interior cladding

To take full advantage of the potential of humidity-variable vapour control membranes to provide protection against moisture damage to structures, diffusion-open cladding should be installed internally, over the vapour control membrane – e.g. gypsum boards or wooden board cladding. Diffusion-inhibiting layers such as OSB or multi-layer wooden panels hinder drying out to the inside in summer.

Correct work process provides protection against condensation

To avoid condensation formation, the vapour control and airtightness layer should be completed immediately after the installation of insulation materials. Blown-in insulation should be inserted immediately after airtight sticking of the membrane. If necessary, carry out this work gradually in steps. This applies particularly to work carried out in winter. Ventilate any increased relative humidity quickly and systematically.

Note for DIY enthusiasts

Install the vapour control membrane at the same time as the thermal insulation. If the thermal insulation is left without a vapour control for a long period in winter, there is a risk of condensation formation.

Moisture due to normal use

The diffusion resistance of INTELLO has been chosen to ensure that there is a reliable vapour-controlling effect even in the case of high indoor humidity, which can occur in new buildings as a result of construction work or during short-term increases in relative humidity in bathrooms or kitchens, for example.

As a rule, moisture due to construction work must be able to escape the building quickly by ventilation through open windows. Dehumidifiers can help to speed up the drying process in wintertime. This helps to avoid permanently high levels of relative humidity.

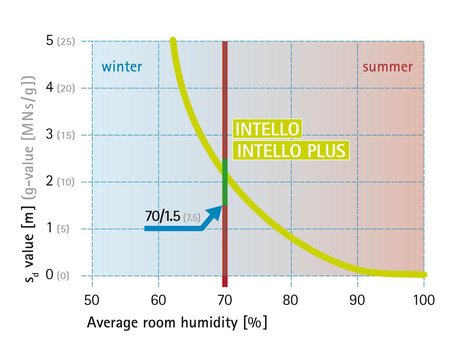

Construction phase: hydrosafe® value (70/1.5 rule)

A vapour control membrane should have a hydrosafe® sd value of 1.5 m (MVTR: 7.5 MN·s/g) in order to protect structures against dampness even in the case of the increased relative humidity that can be present during construction work.

The hydrosafe® value specifies how well sealed a humidity-variable vapour control membrane still is at an average humidity of 70%. Average humidity of 70% will be present if there is 90% indoor air humidity and 50% humidity in the space between the rafters, for example; this level of indoor air humidity can occur when installing screed or plastering walls. The requirement that sd should be > 1.5 m (MVTR: 7.5 MN·s/g) and < 2.5 m (MVTR: 12.5 MN·s/g) comes from the German wood preservation standard and is described in further detail by the 70/1.5 rule. INTELLO fulfils these requirements reliably.

Quality assurance

Airtightness is the critical factor in protecting the thermal insulation structure against moisture damage. pro clima recommends that the airtightness layer should be checked for leaks and that any leaks should be located and rectified using a blower door test.

Proof of durability

There is currently no standard that contains a validation procedure for testing the behaviour and durability of humidity-variable properties. Only vapour control membranes with constant diffusion resistances can be tested in accordance with European standards (EN 13984). For this reason, the durability of the humidity-variable behaviour of INTELLO and INTELLO PLUS has been demonstrated according to a procedure specified by an independent committee of experts of the German Institute of Construction Engineering (DIBt).

As part of this testing, the two vapour control membranes were subjected to accelerated ageing with significantly more demanding conditions (increased temperature and doubled ageing period) as compared with EN 13984. In addition, the permitted deviations of the aged diffusion resistances from the unaged diffusion resistances have been made significantly more demanding in this evaluation as compared to the European standard.

With the European Technical Assessment (ETA-18/1146), INTELLO and INTELLO PLUS have proof of the durability of the humidity-variable properties.

Technical support

If you have questions on applications, please contact our Technical Support.